Foundation of a joint sales and service company - Vemag-Seydelmann NL B.V.

Maschinenfabrik Seydelmann KG and Vemag Maschinenbau GmbH are founding a joint sales and service company in the Netherlands.

From March 1, 2024, Seydelmann's sales activities in the Netherlands will be taken over by the new subsidiary Vemag-Seydelmann NL B.V.

Continuity is also ensured for the after-sales area and service in the Netherlands. The seamless transition will take place on 01.07.2024.

It is of the utmost importance that you, our customers, receive optimal support at all times.

Selo B.V. and Maschinenfabrik Seydelmann KG have been working closely together in the Netherlands for over 70 years. During this time, we have successfully implemented numerous projects together in various industries and put well over 300 machines into operation. At the same time, Selo has managed to establish itself very successfully as an independent supplier and manufacturer of process and cooking systems, which has increasingly become its core business. Against this background, a joint approach was found that offers both companies and, above all, their customers even better prospects for the future.

With the founding of the new joint company, Vemag-Seydelmann NL B.V., two strong partners have come together and, in addition to the broader portfolio, can also provide optimum support in planning, advice and service quickly and competently. Maschinenfabrik Seydelmann as a manufacturer of food processing machines and Vemag Maschinenbau as a manufacturer of food filling machines are even more focused on the requirements of customers in the Netherlands

We would like to thank Selo and the entire team for the many years of friendly, reliable and successful cooperation.

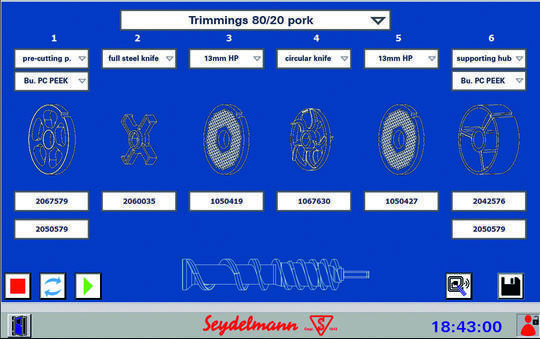

Visual cutting set detection

It usually only takes a few minutes to install a grinder cutting set, but there are many sources of error. Adhering to the correct sequence and installing the correct individual parts is of immense importance - for product quality, product safety and for the service life of the cutting set parts and the entire machine.

The visual cutting set recognition system developed by Maschinenfabrik Seydelmann KG makes it possible to establish a direct link between the products to be processed and the required cutting set, including the correct installation sequence, and to link this with the machine control system. This means that the machine only starts up if the cutting set stored in the recipe has been installed in the correct installation sequence. This is achieved by means of data matrix codes on the cutting set parts, which must be scanned before installation. The control display, which shows the individual cutting set parts, provides assistance for the operator. Clear and immediate feedback to the operator is guaranteed before any potential damage occurs. Accidental incorrect installation is no longer possible.

Linking the cutting set parameters to the recipe control also ensures that the optimum speeds and other processing parameters are always maintained. Each recipe has the appropriate cutting set stored and queries all the required parts before starting the machine.

In the case of hole plates, the applied matrix code also serves as an indicator of the wear limit. Once this has been reached, it can no longer be read by the scanner.

Incorrect products or machine damage caused by installation errors can be reliably avoided with visual cutting set recognition and even non-specialist personnel can carry out the installation - resulting in enormous savings potential.

This solution will be exhibited at Anuga FoodTec, Hall 9.1, Stand A10.

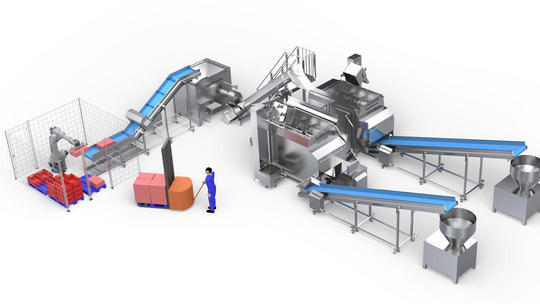

Full automation in production lines - with robots

In the food industry, and especially in the production of meat products, automation of production has long been a reality. Processed products are increasingly transported from one production step to the next using appropriate conveyor technology, such as conveyor belts, screw conveyors or pumps, and the raw materials are automatically fed in the required quantities. Only the first step in the chain still requires strenuous manual labor - when emptying the standard transport containers (E2 crates) or when placing blocks of frozen meat.

Maschinenfabrik Seydelmann has been driving the development of the industry for over 180 years now and has also risen to this challenge. By using an industrial robot that complies with the strict hygiene requirements in food production, this task can be carried out precisely and around the clock. Precisely matched to the production speed of the machines to be loaded, a higher throughput is achieved while minimizing the risk of contamination and reducing the strain on personnel.

The robot can either automatically load a conveyor belt - possibly with analytics and foreign body/metal detection - or directly feed various machines, such as grinders, bowl cutters or mixers. The empty containers are then stacked back onto a pallet.

Various grippers are precisely matched to frozen meat blocks, E2 crates or other containers - an interchangeable system is possible - and thus ensure gentler handling of the product and container thanks to consistent forces. When emptying E2 crates, they are gripped securely and emptied completely by controlled shaking. The edges are not knocked against metal edges or plates, which prevents plastic from splintering and thus contamination.

The use of robot technology closes a gap in the automation of production, improves work ergonomics, enables higher throughput, reduces the risk of contamination and saves costs.

Maschinenfabrik Seydelmann offers various robot systems including grippers, protective housing and the necessary programming. This solution will be exhibited in a production line at Anuga FoodTec, Hall 9.1, Stand A10.

把最好掌握在手中

赛德曼机械制造公司致力于高品质食品加工机器的开发,生产和销售已超过180年。 创新和引领潮流的机器由这家位于德国南部的现代化家族企业设计和制造的。赛德曼作为一家全球化公司,绞肉机、斩拌机、搅拌机,乳化机和生产线销往五大洲的150多个国家/地区。赛德曼机器以经久耐用、高效和最高品质,确保客户的产品具有竞争优势。

靠近客户

为我们的客户提供服务,并向他们学习,使我们能够识别和了解他们的需求和期望。这种关系是能够开发、提供和实施保证长期满意的解决方案的前提。

质量管理

赛德曼机器由最高质量的材料和部件制造,并采用最新技术操作。自公司成立以来,我们在Aalen规划、设计和制造所有机器--"德国制造"。

革新

几十年来与从本地区到国际食品行业的肉商的紧密合作,使我们对日常的生产常规有了深刻的了解,也有了丰富的应用经验。

服务实力

开发最佳的个性化解决方案以及专业的机器安装是Seydelmann服务的一部分,同时还可以提供专业的机器指导和技术咨询。