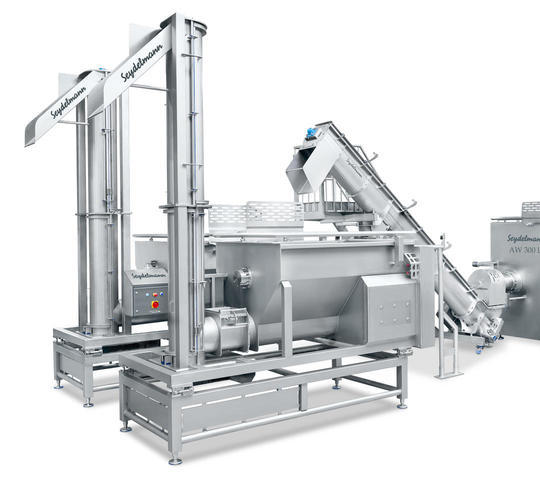

Conveying and storage technology

Seydelmann machines can be combined into customized (semi-)automated complete solutions or they can be integrated into existing production processes. We are not only convincing as a manufacturer of processing machines - we supply the entire production line, from the machine to the conveyor belt.

All the necessary means of transporting the product, like conveyor belts, screw conveyors, and pumps are tailored exactly to the individual machines and the steps in the

production process. The conveyor systems replace the labor and time consuming transport of the material via trolleys between the individual steps in the production process.

Storage containers built into the Production Line offer a space-saving and efficient alternative to temporary storage of the material in trolleys.

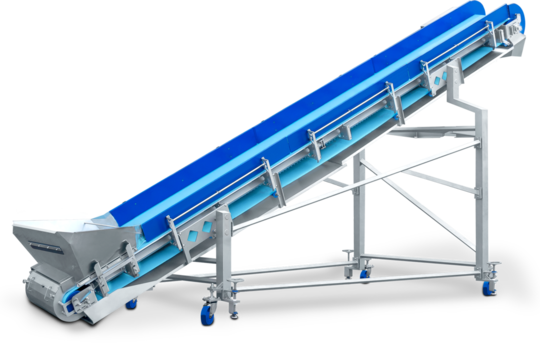

Conveyor belts

The open construction of the machine frame and belt frame without closed tube profiles ensures faster cleaning. All areas are easily accessible. Advantages of loading with conveyor belts are the high transport capacity and the low level of safety risks and dangerous areas. In addition, conveyor belts ensure continuous loading.

Screw conveyors

The main advantage of loading via screw conveyor is the small floor space due to the steep angle which can be fixed as needed with the height adjustment. Screw conveyors are made entirely of stainless steel. All surfaces and parts in contact with product are plastic-free. They are equipped with closed interlocked lid as a standard. Thus, highest hygienic standards are fullfilled. The construction is very robust and ensures continuous feeding.

Retractable Screw Conveyor

With the pneumatically retractable inclined screw conveyor, Maschinenfabrik Seydelmann KG offers its customers an innovative solution for the most diverse challenges.

By eliminating the cleaning staircase, the dimensions are significantly reduced in width and height, which makes it much easier to maneuver during operation and to bring in the conveyor technology. At the same time, occupational safety is improved, as cleaning, which is easy anyway thanks to the sophisticated hygienic design, can now be carried out at ground level. The conveying height and thus the conveying distance can be designed according to customer specifications. Integration into a fully or semi-automatic production line is possible as usual.

(Vertical) Buffer screw conveyors

Optionally, the screw conveyors can be equipped with an integrated storage hopper. The buffer screw conveyors combine a buffer storage tank with a conveyor screw. They ensure a constant and optimal product flow by offering the possibility to buffer the material, when subsequent machines are already filled. Like all machines, they are manufactured according to the Seydelmann Hygienic Design and guarantee easy cleaning.

Unlike the buffer screw conveyor, the vertical buffer screw conveyors convey vertically upwards, making them more compact and optimally suited for production rooms with smaller space requirements. Two cleaning hatches above the horizontal and on the vertical conveyor screw allow this design to be cleaned easily and quickly.

Pumps and pipe systems

In Production Lines, pumps are usually used to transport the finished product. Screw spindle pumps ensure gentle transport of the goods with minimal warming. The pumps are wear-free and non-abrasive. No metal chips are introduced into the final product. All parts coming into contact with the final product are made of stainless steel. The drive and the pump are built into a closed stainless housing.

Loading devices

Integrated hydraulic loading device

The Grinders can be equipped with an integrated hydraulic loading device. The loading device is very quick and easy to clean, requiring very little space.

Loading device for large containers

The loading device for large containers enables quick and efficient loading and can be customized to suit different container sizes.

Vertical loading device

The Mixers, Grinders, and Emulsifiers can be loaded via a vertical loading device which can either be floor-mounted or mounted on the machine.

Contact us

Do you need conveying or storage technology for your plant or are you looking for an individual complete solution?

Send us your inquiry via the following contact form.

We are looking forward to your inquiry!